Page 3 of 6

Re: My R4

Posted: Wed Mar 02, 2016 1:44 am

by joshua102

The rubber coating on the Oil pump drive gear the gear has 6 lightening hole with only 3 uncoated (to allow oil pump to be installed). i used a lathe at work, and a plumbers blow touch to removed any small bits.

The BDK water pump kit comes with a very simple controller with two adjustable pots (on and off), i'm sure if you dropped them an e-mail they would sell you just the controller.

Joshua

Re: My R4

Posted: Wed Mar 02, 2016 10:15 pm

by maccas

Zeeltronic do an electronic water pump controller. Might be worth giving them an email.

Dan

Re: My R4

Posted: Wed Mar 09, 2016 2:51 pm

by Maelstrom

Thanks Dan. I got the details from them.

Re: My R4

Posted: Sat Mar 12, 2016 10:40 am

by Evilchicken0

When you paint bolts you don't really want paint on the threads, so ... order a pizza

Cut the lid off the delivery box and make holes in it with a screwdriver. Wire brush the bolt heads then drop them in petrol, it cleans the threads too. Wipe them in a cloth and stick them in the holes.

Now you can spray them in batches and they're held upright while they dry and you can find the bolts for each casing

Re: My R4

Posted: Mon Mar 14, 2016 5:54 am

by Maelstrom

Thanks Evil but the bolts have to be blasted before painting and then baked in the oven.

Re: My R4

Posted: Thu Mar 17, 2016 12:45 pm

by Evilchicken0

Up to you how you prep them, but putting them on a board will make them easier to hold in the oven too

Re: My R4

Posted: Fri Jan 06, 2017 1:38 pm

by Maelstrom

Gee it has been so long that it nearly fell off the forum.

Prepped the top end and painted

Re: My R4

Posted: Sun Jan 08, 2017 7:42 pm

by Evilchicken0

Looks nice

Re: My R4

Posted: Sun Mar 26, 2017 11:05 am

by Maelstrom

Sneak Peak:

So wings gone.

and off to powder coaters

I am going to make an adjustable stand for it now so I can keep working in comfort.

Cheers

Blair

Re: My R4

Posted: Sat Jul 15, 2017 4:32 am

by Maelstrom

Hi All,

Been too long.

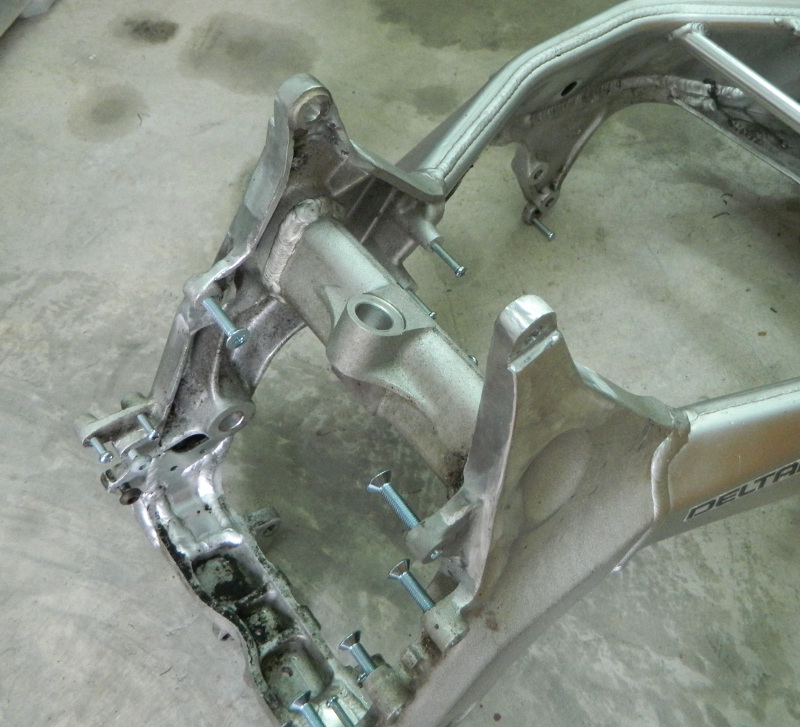

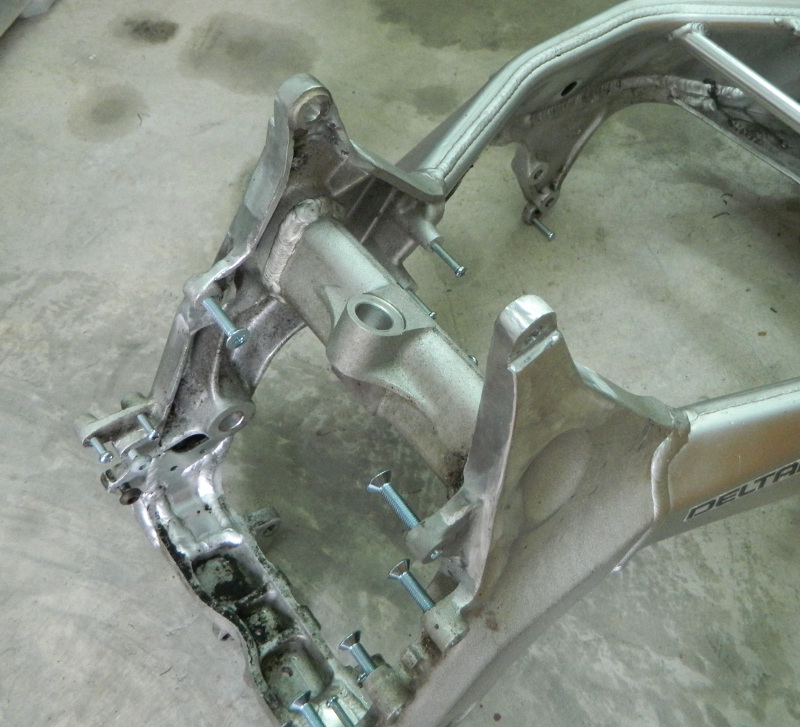

I made a stand with swivel bracket to hold the bike chassis and get to work on the headlights.

Then I had to cut and beef up the Chinese sourced R6 fairing bracket. Notice how thin it is. Also all of the grommet holes are too large, not round and different sizes. If you try to fit the OEM grommets they just flop about. I bored all of mine out to 18mm and used custom size grommets.

To fix the flimsy bracket I welded a piece of 6mm onto it etc, etc. The hole centres are wider on the FZR400 than the R6 so you have to cut and weld that first.

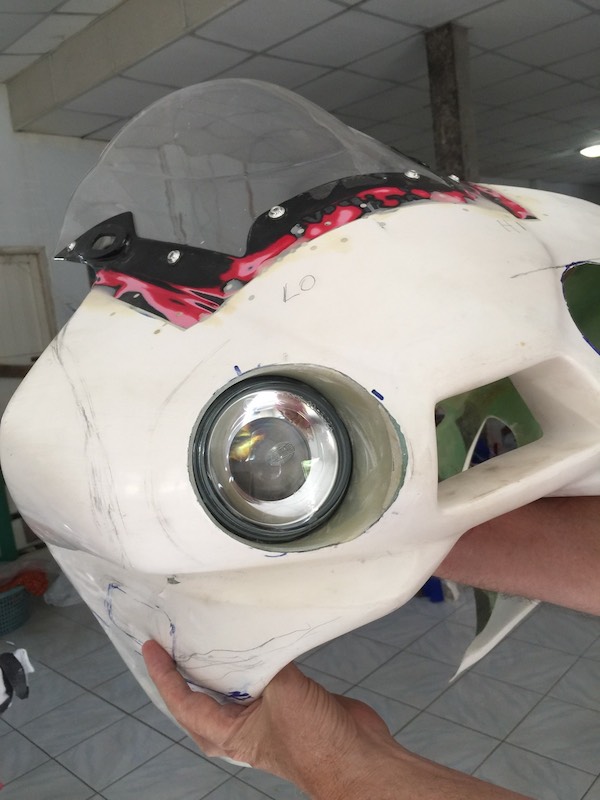

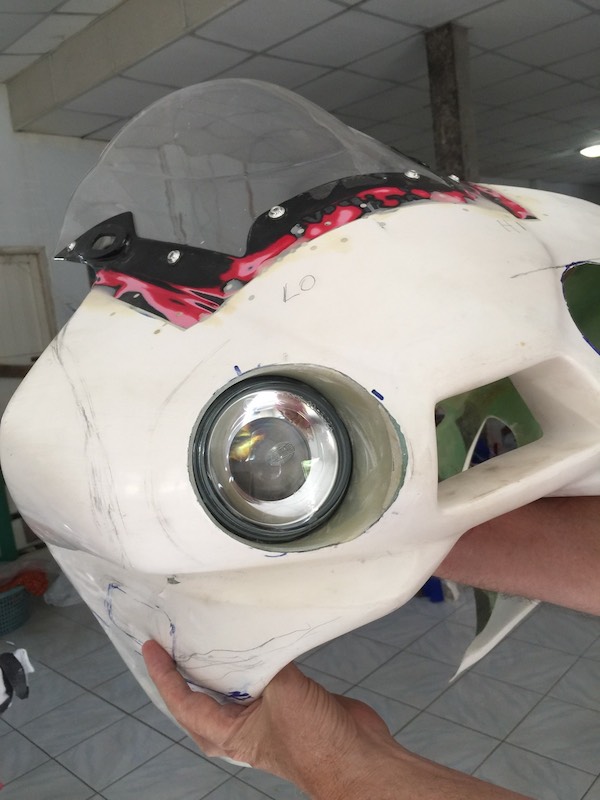

Cut the headlight holes and made fibreglass recesses

I am waiting for lots of bits and pieces now. The headlight bracket will be carbon. Should be some more updates soon as I am working on multiple parts at the same time.

Cheers

Blair