How to fit the 600 into the 3tj

Forum rules

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

-

giller72

- Settled in member

- Reactions:

- Posts: 31

- Joined: Mon Sep 22, 2014 7:14 pm

Re: How to fit the 600 into the 3tj

It is possible that I have a foxeye motor even though it was advertised as a thundercat engine, I'll check the engine numbers tomorrow but I seem to remember the number had 4tv in which I thought indicated a thundercat motor.

Don't get me wrong, I'm chuffed it all lines up and I can get it on the dyno asap...I just feel there must be some logic behind the fact that some seem to line up and others don't

Don't get me wrong, I'm chuffed it all lines up and I can get it on the dyno asap...I just feel there must be some logic behind the fact that some seem to line up and others don't

-

Evilchicken0

- Site Supporter

- Reactions:

- Posts: 9490

- Joined: Tue Apr 29, 2008 8:59 pm

- Bike owned: Bimota SB6 Yamaha FZR 3TJ x2

- Location: Lundin Taan

Re: How to fit the 600 into the 3tj

Me ? I haven't but it might be an idea to look at.

-

giller72

- Settled in member

- Reactions:

- Posts: 31

- Joined: Mon Sep 22, 2014 7:14 pm

Re: How to fit the 600 into the 3tj

I thought I would just update on my Fzr400/600 build, maybe some of this information will be useful to others. The last time I updated I had just checked that the rear wheel aligned with the front sprocket. Even though I have a thundercat engine and a 3tj frame I found no problems with alignment.

The next issue was to wire up the thundercat ECU. I decided to use my FZR400RR race loom and make jumper cables to link the thundercat ECU to the loom; this was pretty easy except I had the 8000rpm tacho error. No matter what I tried I could not avoid it. I tried to replicate the fuel sender with a potentiometer and lamp in series and then set the resistance to fool the ECU into believing I had a fuel sender and a full tank of fuel ( I'm told that when full the fuel sender has a resistance of 1150 ohms). In the end I took a feed from the low tension negative terminal of the coil to run my rev counter. The bike has a stack rev counter and this solved the issue but I'm not sure this would work on a standard set of clocks

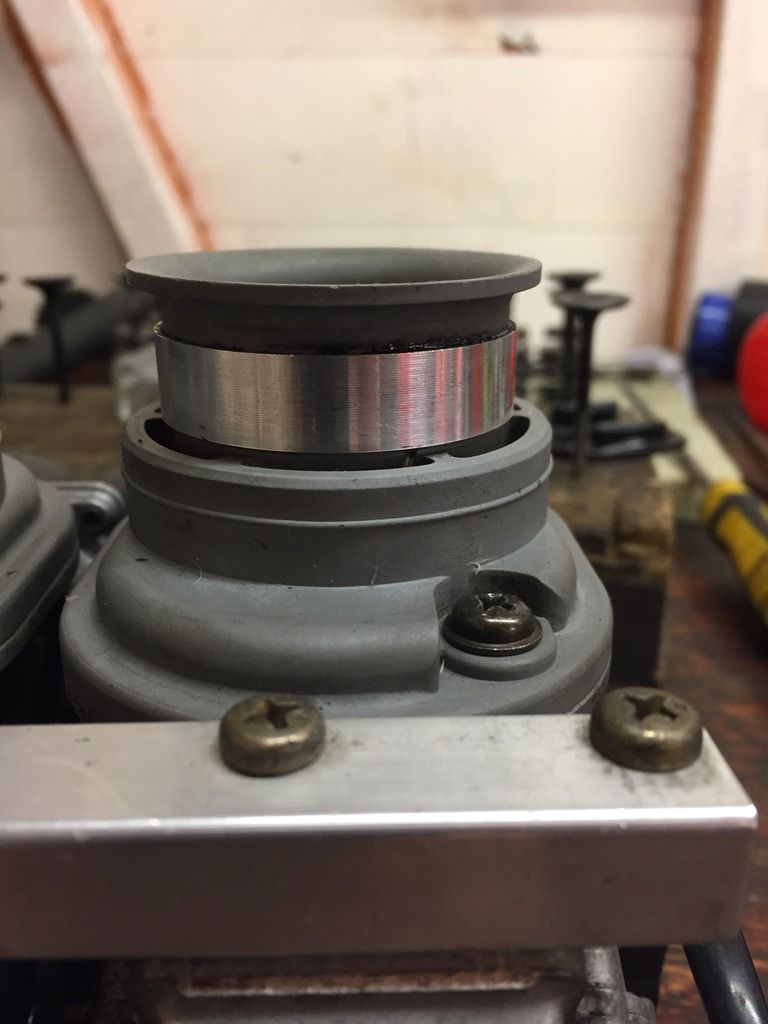

The next issue was the carbs. With a larger and higher engine I could not fit the carbs under the tank, this is because my tank had been altered to run at the TT and so had the base lowered to get a 24l capacity. I decided to shorten the velocity stacks. I cut out about 2.5cm and rejoined the ends:

[img][IMG]http://i58.photobucket.com/albums/g263/ ... cndwkc.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... dtvjie.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... fmqpwd.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... box0ti.jpg[/img][/img]

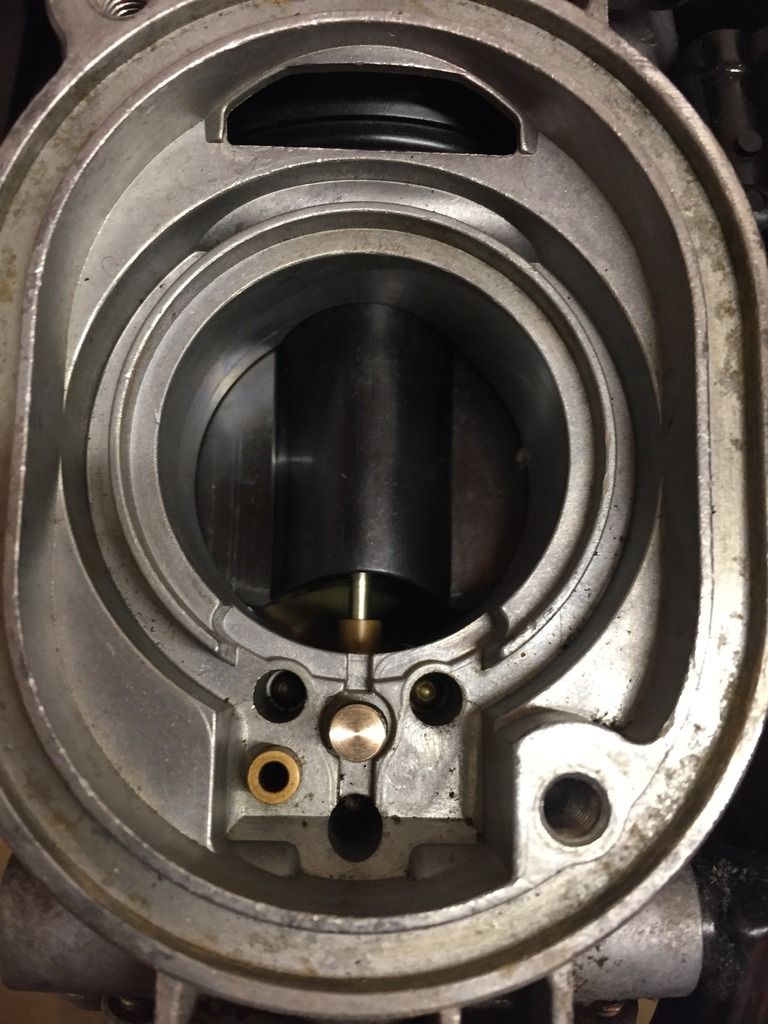

The next issue was to get the fuelling set up, it was running lean all over the place. I was running standard 150 mains and had read ( way back on page 3 or 4 of this thread) that I may need 180 mains to run these carbs without an airbox. After many different dyno runs and no success, I took the bike to SDC performance to help set it up and it took Gary a couple of runs before deciding to block the air correctors and go back to 150 mains. A bit later I made up some brass plugs and blocked all four correctors

[img][IMG]http://i58.photobucket.com/albums/g263/ ... xcrgwb.jpg[/img][/img]

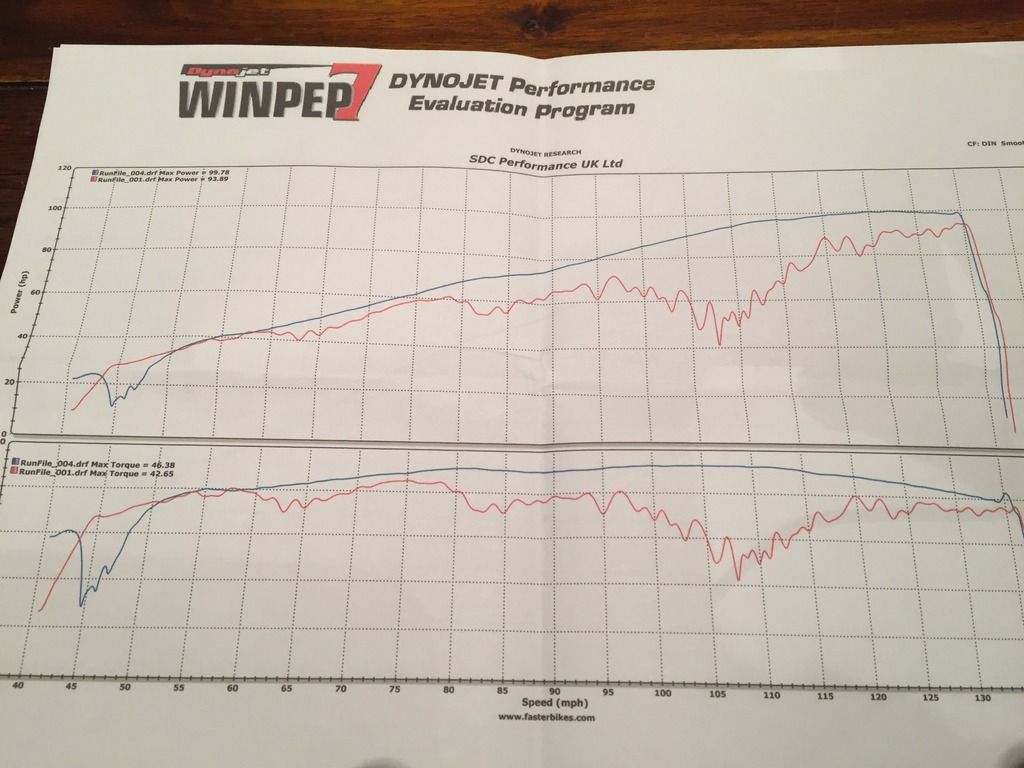

The results were very impressive:

[img][IMG]http://i58.photobucket.com/albums/g263/ ... c9wlve.jpg[/img][/img]

The red line shows the bike running 170 mains and the blue line is with 150 mains and blocked air correctors. I have to say Gary at SDC performance was very knowledgeable and found a solution to the poor fuelling extremely quickly . All up the bike now makes roughly 100hp and weighs about 155kg fully fuelled.

Now that the bike is finally finished it will compete in the Thunderbike sport championship at Bemsee, hopefully it will have the handling of the 400 with the power to keep larger bikes behind on the straights. I’m very much looking forward to riding and racing it.

[img][IMG]http://i58.photobucket.com/albums/g263/ ... m3mly4.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... 4epgwq.jpg[/img][/img]

The next issue was to wire up the thundercat ECU. I decided to use my FZR400RR race loom and make jumper cables to link the thundercat ECU to the loom; this was pretty easy except I had the 8000rpm tacho error. No matter what I tried I could not avoid it. I tried to replicate the fuel sender with a potentiometer and lamp in series and then set the resistance to fool the ECU into believing I had a fuel sender and a full tank of fuel ( I'm told that when full the fuel sender has a resistance of 1150 ohms). In the end I took a feed from the low tension negative terminal of the coil to run my rev counter. The bike has a stack rev counter and this solved the issue but I'm not sure this would work on a standard set of clocks

The next issue was the carbs. With a larger and higher engine I could not fit the carbs under the tank, this is because my tank had been altered to run at the TT and so had the base lowered to get a 24l capacity. I decided to shorten the velocity stacks. I cut out about 2.5cm and rejoined the ends:

[img][IMG]http://i58.photobucket.com/albums/g263/ ... cndwkc.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... dtvjie.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... fmqpwd.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... box0ti.jpg[/img][/img]

The next issue was to get the fuelling set up, it was running lean all over the place. I was running standard 150 mains and had read ( way back on page 3 or 4 of this thread) that I may need 180 mains to run these carbs without an airbox. After many different dyno runs and no success, I took the bike to SDC performance to help set it up and it took Gary a couple of runs before deciding to block the air correctors and go back to 150 mains. A bit later I made up some brass plugs and blocked all four correctors

[img][IMG]http://i58.photobucket.com/albums/g263/ ... xcrgwb.jpg[/img][/img]

The results were very impressive:

[img][IMG]http://i58.photobucket.com/albums/g263/ ... c9wlve.jpg[/img][/img]

The red line shows the bike running 170 mains and the blue line is with 150 mains and blocked air correctors. I have to say Gary at SDC performance was very knowledgeable and found a solution to the poor fuelling extremely quickly . All up the bike now makes roughly 100hp and weighs about 155kg fully fuelled.

Now that the bike is finally finished it will compete in the Thunderbike sport championship at Bemsee, hopefully it will have the handling of the 400 with the power to keep larger bikes behind on the straights. I’m very much looking forward to riding and racing it.

[img][IMG]http://i58.photobucket.com/albums/g263/ ... m3mly4.jpg[/img][/img]

[img][IMG]http://i58.photobucket.com/albums/g263/ ... 4epgwq.jpg[/img][/img]

-

Evilchicken0

- Site Supporter

- Reactions:

- Posts: 9490

- Joined: Tue Apr 29, 2008 8:59 pm

- Bike owned: Bimota SB6 Yamaha FZR 3TJ x2

- Location: Lundin Taan

Re: How to fit the 600 into the 3tj

Use the "direct link" from photobucket pasted between the [im g] [/im g] I think there are max sizes for a pic, you can control them when you upload them through the settings on photobucket

This sounds impressive - I might try to get down to a Bemsee meeting and have a look

This sounds impressive - I might try to get down to a Bemsee meeting and have a look

-

chrisexup

- Settled in member

- Reactions:

- Posts: 34

- Joined: Sun Nov 24, 2013 12:48 pm

- Bike owned: fzr6003tj kr1-s d675 ypvs350

- Location: cheshire, uk

Re: How to fit the 600 into the 3tj

giller72 wrote:I thought I would just update on my Fzr400/600 build, maybe some of this information will be useful to others. The last time I updated I had just checked that the rear wheel aligned with the front sprocket. Even though I have a thundercat engine and a 3tj frame I found no problems with alignment.

The next issue was to wire up the thundercat ECU. I decided to use my FZR400RR race loom and make jumper cables to link the thundercat ECU to the loom; this was pretty easy except I had the 8000rpm tacho error. No matter what I tried I could not avoid it. I tried to replicate the fuel sender with a potentiometer and lamp in series and then set the resistance to fool the ECU into believing I had a fuel sender and a full tank of fuel ( I'm told that when full the fuel sender has a resistance of 1150 ohms). In the end I took a feed from the low tension negative terminal of the coil to run my rev counter. The bike has a stack rev counter and this solved the issue but I'm not sure this would work on a standard set of clocks

The next issue was the carbs. With a larger and higher engine I could not fit the carbs under the tank, this is because my tank had been altered to run at the TT and so had the base lowered to get a 24l capacity. I decided to shorten the velocity stacks. I cut out about 2.5cm and rejoined the ends:

The next issue was to get the fuelling set up, it was running lean all over the place. I was running standard 150 mains and had read ( way back on page 3 or 4 of this thread) that I may need 180 mains to run these carbs without an airbox. After many different dyno runs and no success, I took the bike to SDC performance to help set it up and it took Gary a couple of runs before deciding to block the air correctors and go back to 150 mains. A bit later I made up some brass plugs and blocked all four correctors

The results were very impressive:

The red line shows the bike running 170 mains and the blue line is with 150 mains and blocked air correctors. I have to say Gary at SDC performance was very knowledgeable and found a solution to the poor fuelling extremely quickly . All up the bike now makes roughly 100hp and weighs about 155kg fully fuelled.

Now that the bike is finally finished it will compete in the Thunderbike sport championship at Bemsee, hopefully it will have the handling of the 400 with the power to keep larger bikes behind on the straights. I’m very much looking forward to riding and racing it.